Water jet explained in detail

Insight into what water jet cutting is, and what it can do for you.

Water jet cutting

An excellent cold-cutting process that is capable of cutting virtually any material to virtually any shape.

- So what is water jet cutting?

- How does water jet cutting work?

- Is waterjet cutting accurate?

These Questions and more are answered here.

So what is water jet cutting?

Water jet profiling is a cold cutting/erosion process that emits no hazardous materials. With a very tight tolerance control, waterjet cutting has no heat affected zone (HAZ) which is common in flame, plasma, or laser profiling, and with a standard jet width (known as the kerf) of approximately 0.8mm to 1.2mm diameter, extremely intricate designs can be cut. Should a smaller kerf be required then we can use Micro jet facilities.

The resulting clean-cut edges require little or no finishing. We utilize the process to fulfill direct cutting requirements for small and large-scale industrial projects, precision engineering, design and craft projects as well as sculptural and public art commissions.

Water jet cutting is a process with endless possibilities which allows us to utilize it and realize your ideas, designs, and individual cutting requirements. Simply provide us with either a CAD drawing, shape, sketch, or template and we can work from this to create the data required to program our associate’s machines.

How does waterjet cutting work?

How does waterjet cut materials like steels, stainless steels, brass, bronze, copper, Aluminium, glass, ceramics, stone, wood, mdf, armour plating, plastics etc..

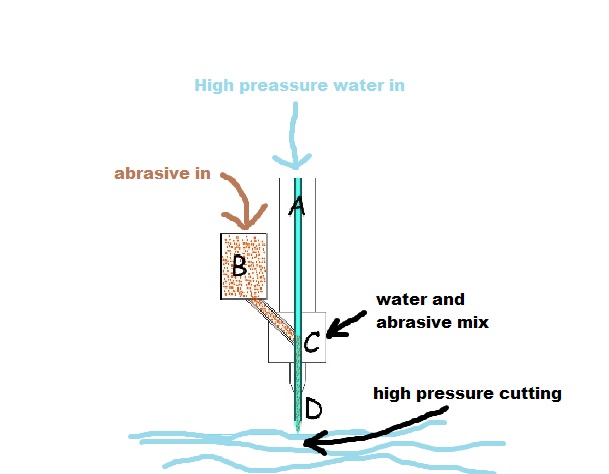

The abrasive waterjet process:

- Shown in this very simple diagram above, the high-pressure water comes in through a tube noted (A)

- An abrasive material is fed through a hopper marked (B) generally garnet is used, which is like a course sand

- The garnet is mixed into the high-pressure water stream in a mixing chamber marked (C)

- The high-pressure water stream now mixed with an abrasive material is then focused through a tube marked (D)

- This fine abrasive waterjet is the cutting edge used to cut the materials.

However, it is still a floppy cutting tool and some jobs need care and thought to ensure they are cut well and accurately.

Is waterjet cutting accurate?

Waterjet cutting can be extremely accurate when used right and on the right work, but a lot of consideration needs to go into the particular material and part being cut for best accuracy.

For instance, waterjet cutting is very accurate when cutting steel but the steel itself can be full of internal stresses, from when it was rolled at the mill, to the flattening processes when it was de-coiled and perhaps any heat treatments it undergoes prior to waterjet cutting.

The waterjet process itself is a low heat process so there is no heat affected zone (HAZ) common in other processes…But when it is cutting parts from stressed materials then the material can move during the process, which could end up with inaccuracies. A careful selection of materials, good work holding, considerate programming, and machining strategies will all assist with the best most accurate parts.

Waterjet Cut Quality and Accuracy

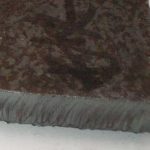

The cut-edge quality is greatly affected by the speed and setup of the waterjet cutting machine. Shown here is a typical example of cut quality on some Metal. The lower the speed the more accurate and better quality the cut.

So at 100% speed, the Striations on the edge are very coarse, this is caused by the effect of the waterjet flailing around as it is trying to cut through the material.

A 100% speed is normally just used for rough separation cuts in materials where quality and accuracy are not important.

You can see in the pictures how the Striation effect is greatly reduced as the speed is reduced and the most accurate cutting is generally done around the 40% speed to 20% waterjet speed.

Basically The higher the edge quality and the more accuracy required results in a much slower process that costs more to produce.

Generally, work will be cut to +/- 0.2mm ish with our general waterjet cut work but on more accurate work we will ensure test cuts are done and calibrations to the machine are performed to get as close as possible to your preferred tolerance, I am sure you will find our quality provided as good as it gets.

Waterjet profiling an overview

With Waterjet profiling, the ability to cut virtually any 2-dimensional shape in virtually any material with water and abrasives makes the process adaptable for all sorts of different projects.

Waterjet cutting is an excellent cold-cutting process with minimal or no finishing. With a tight tolerance control and no heat-affected zone (HAZ) that is common in flame, plasma, and laser profiling. Waterjet generally has a standard jet width of approximately 1mm to 1.2mm diameter.

Enabling extremely intricate designs that can be cut. We can also procure parts from machines with a much smaller jet diameter/kerf if required.

As it is an erosion process, the range of materials that can be water jet cut is vast, only ever limited by the material’s characteristics. This means reflective, fragile, soft, hard materials and even hardened tool steels and glass can be cut. The list is endless.

The latest computer technology is selected to control the machines and various other additional processes can be made use of, including pre-drilling, automated loading, and dynamic Waterjet cutting heads which enables us to offer straighter edges and an all-around more accurate cut.

We can also offer to procure parts to be cut on multi-axis machines or robotic arm-type machines.

Very powerful job nesting programs are used that have a range of features to assist in waterjet profiling your parts, making the best use of materials and time.

Waterjet Cutting Compared to Laser, Plasma, or Flame cutting

We believe waterjet cutting offers a much better and more accurate part from the process than other processes like laser, plasma, or flame cutting so while these other processes can sometimes offer low-cost parts, especially in thinner materials it can be more cost-effective spending a bit more money and having waterjet cut parts made. We have some comparison pictures below for you to see but some of the benefits of waterjet cutting over laser cutting, plasma, or flame cutting are:

Burr-free edges with waterjet cutting:

The cut edge on waterjet cut parts is excellent resulting in minimal or no further edge preparation for use. Different materials behave very differently but in general, the edge is pretty much burr-free, and even when there is a burr present it comes off very easily with a bit of scotch brite or something similar and in the event you need to prepare the edges with a champhre or a radius either by machining or other edge preparation technique, you will be pleased to find that there is no heat affected zone (HAZ) common with almost all other forms of profiling. The water doesn’t change the edge properties due to heat, so the material stays in its original form, it doesn’t harden or soften and this will mean your cutters will last much longer.

No heat affect zone (HAZ) with waterjet cutting:

Laser, plasma, and flame cutting use a lot of heat in their cutting process and this results in changing the properties of the materials being cut e.g. some materials will become hard and brittle which makes them hard to machine, etc.. on further operations.

Also, the dross/slag created by the heat processes can sometimes be very difficult to get off, which means expensive manpower on secondary operations, and with the heat affected edge, the contaminants left behind from laser or plasma cutting can affect and contaminate any welding, which is more of an issue with specialist alloys and specialist metals.

With waterjet, the edge is not contaminated and therefore a pleasure to weld.

So whilst waterjet can sometimes be more expensive it can work out cheaper in the long run.

Sharp, crisp, and defined edges:

With other processes like laser, plasma, and flame cutting the edges can be molten, rounded, and under-defined, with waterjet the edges are clean, crisp, and well-defined.

Cut closer to the edge and other features with waterjet cutting:

With other processes like Laser cutting and plasma cutting the heat used in the process can build up especially when cutting lots of holes or features together or cutting close to the edge. With Waterjet cutting there are no heat issues so we can cut holes and features close together or close to the edges.

Water jet cutting

versus Laser or Plasma cutting

To give you some comparisons we have listed some samples of the different processes compared to waterjet cutting, please note we cut all the waterjet samples through our facilities, the green boxes are waterjet cut the red boxes are comparisons cut with the different process as indicated,

WATER JET CUT 5mm Steel

5mm thick steel part with very clean edges and features

This is one of a set of parts for a steel fabrication, the parts come from the machine so clean and accurate that they basically clip together and could be welded with virtually no pre-finishing. This means fewer man-hours spent on parts that can save a lot of money in the long run.

LASER CUT 5mm Steel

5mm thick steel part with fairly rough edges

This set of laser-cut parts which were cut from hot rolled steel plate had fairly rough edges, dross built up on them that needed cleaning up as well as heat-affected edges that left a dark greyscale buildup that needed removal and cleaning before welding. All this takes time, effort, and skilled manpower.

WATER JET CUT 20mm Steel

20mm thick steel part with crisp clean edges

This part was waterjet cut from a 20mm thick hot rolled steel plate and it demonstrates the crisp clean accurate edges achievable with water jet cutting especially in thicker materials like hot rolled steel plate.

PLASMA CUT 20mm Steel

20mm thick steel Part with Poor edges

This part was cut with the plasma cutting process from a 20mm thick hot rolled steel plate. It forms part of a drain cover plate. if you look at the edges you will see a rougher cut, rounded edges, part of a corner missing and heat-affected zones around the cut.

WATER JET CUT 20mm Steel

20mm thick steel part with a nice detailed form

another part waterjet cut from a 20mm thick hot rolled steel plate.

You can see a radius feature accurately waterjet cut into this part, this half-round feature sits on top of a male part and acts as a pivot joint. it needed very little post-finishing and fit perfectly in the design.

PLASMA CUT 20mm Steel

20mm thick steel Part with rough edges

a very rough cut edge from plasma cutting, we were supplied this by a customer and we were asked to cut the edges down to neaten them up. once we waterjet cut them the customer was happy.

WATER JET CUT 40mm Steel

40mm thick steel part with very accurate features

This is a steel part waterjet cut from a 40mm thick Steel plate, note even though the thickness is Quite thick the edges are still very crisp and the Features are well defined, even the 3.3mm diameter hole in the bottom of the V. Also see How Straight and sharp the edges look.

I’d Like to see this done by other methods

Waterjet detailed cuts with no heat distortion and post-finishing!

Detailed cuts:

With waterjet profile cutting, very detailed cuts can be performed with no heat-affected zones and minimal / no post-finishing. The “Town Quay Park” sign above was a water jet profile cut in a 6mm thick steel plate. Whilst this can be done with other processes like laser or plasma, the crisp clean, and detailed cuts from the waterjet process make the work a lot better.

No heat distortion:

hot rolled steel plate when produced has heat stresses induced into the plate through the manufacturing process, when cutting this with heat processes like laser or plasma the internal stresses can be relaxed/relieved and other heat stresses will be applied / induced resulting in potential issues from flatness and warping, with waterjet profile cutting there is no heat put into the material so there is no change to the internal stresses or additional stresses put in.

Post finishing:

Little or no post-finishing of your cut parts, can save an immense amount of time and money in fabrication time.

Making good quality waterjet cutting supplied by Safire a cost-effective solution

Very High-Quality detailed cuts

A fountain base cut from corten steel

Close-up view of the detailed cuts

Waterjet cutting gives very clean cuts with high detail and great quality.

This project for a corten steel fountain base which was also manufactured by us at our workshops, was waterjet cut from corten steel plate. looking close up you can really appreciate the quality of the patterned holes cut really close together and there are over 4000 feature holes water jet cut into this corten steel design.

Cutting this many features can be quite demanding on computer software and machine controllers but here at Safire, we are able to control the digital files to enable us to perform this type of work.

With this many feature holes cut very close together into corten steel plate, water jet cutting is the only real solution due to the cold cutting process. Simply put, if this were cut by other processes the heat build-up would have distorted the plates so they would not have sat flat at all, also the amount of post-finishing would have caused higher costs from the manpower required to finish it.

It is no wonder the client chose us and our process options over other cutting methods as they wanted a nice flat and good-looking design at the end.

This is a clear demonstration of how Safire waterjet cutting can be utilized for your projects!

The finished job installed

Why Use Safire Waterjet?

We do not have in-house waterjet cutting anymore, so Why use us?

A decision was taken in 2023 to change the way we work to better fulfill our client’s needs. We select our associates carefully making sure they can do what we need and what we ask.

Whilst you are free to shop around to get what you want it can be difficult to get what you need, especially if you don’t fully understand the process and technologies available.

bearing in mind a lot of waterjet cutting companies are generally stone and tile cutting specialists and whilst they can cut 2D shapes on their machines in other materials as well, We are engineers with an eye for design and engineering view of our work, we use the latest cad software to design with and utilize a very wide variety of other engineering facilities at our disposal, this results in the best thought and effort being put into your project.

We will look at your project from a different angle giving you the best service we can!

We are engineers and waterjet cutting specialists, we adopt an engineering mindset with our work and have a keen eye for design.

So you can be assured of your project being thought about, handled, and processed with the care and attention of design engineers.

A high-quality job designed and manufactured for a super yacht.

Waterjet cut mainly from 3mm brass sheet, but with machined elements and an aluminum substructure and fabricated by Safire.

High-quality work – Great service – Contact Safire.